News Center

27

2017

-

12

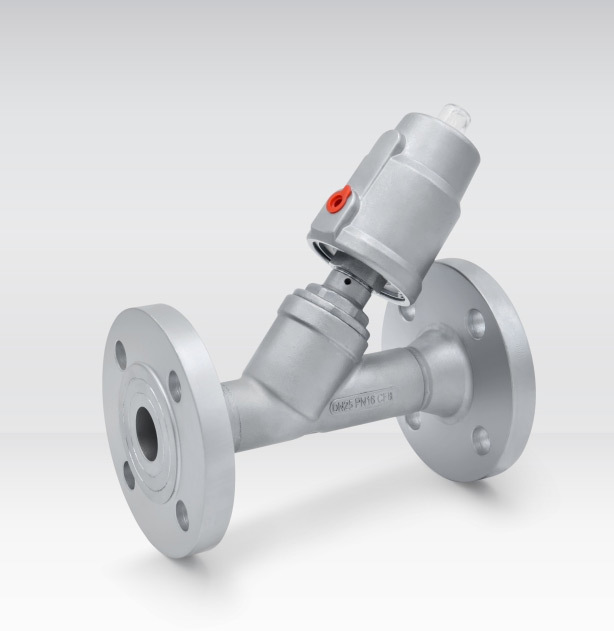

Briefly describe the characteristics and performance of knife gate valve

Knife gate valves entered my country in the 1980s. In less than two decades, its scope of use has expanded from the general field to a wider range of industries.

Knife gate valves entered my country in the 1980s. In less than two decades, its scope of use has expanded from the general field to a wider range of industries.

1. The development history of knife gate valve

Knife gate valves entered my country in the 1980s. In less than two decades, its scope of use has expanded from the general field to a wider range of industries. Coal preparation, gangue discharge and slag discharge from mines and power plants. It has developed into urban sewage treatment, and has developed from general industrial pipelines to professional pipeline systems such as food, sanitation, and medicine.

Second, the characteristics of knife gate valve

The ultra-thin knife gate valve completely solves the large flow resistance of ordinary gate valves, flat gate valves, ball valves, globe valves, regulating valves, butterfly valves, etc. with its advantages of small size, small flow resistance, light weight, easy installation, and easy disassembly. , Heavy weight, difficult installation, large area and other difficult problems. After the emergence of knife gate valves, a large number of general shut-off valves and regulating valves have been replaced. To date, the world's largest consumption of knife gate valves is the United States and Japan.

3. Precautions and model of knife gate valve in use:

The opening and closing part of the knife gate valve is the gate, and the movement direction of the gate is perpendicular to the direction of the fluid. The manual knife gate valve can only be fully opened and fully closed, and cannot be adjusted or throttled. The gate has two sealing surfaces. The two sealing surfaces of the most commonly used mode gate valve form a wedge. The wedge angle varies with the valve parameters, usually 50. The gate of the wedge knife gate valve can be made into a whole, called Rigid gate; it can also be made into a gate that can produce slight deformation to improve its manufacturability and compensate for the deviation of the angle of the sealing surface during the processing. This kind of gate is called an elastic gate when the knife gate valve is closed, the sealing surface It can only rely on the pressure of the medium to seal, that is, rely on the pressure of the medium to press the sealing surface of the gate to the valve seat on the other side to ensure the sealing of the sealing surface, which is self-sealing. Most knife gate valves adopt forced sealing, that is, When the valve is closed, the gate must be forced to the valve seat by external force to ensure the tightness of the sealing surface.